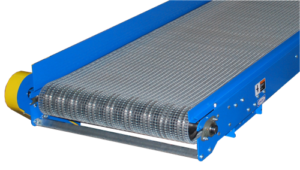

Balanced weave mesh belts are the important component for high temperature furnace conveyor the width can be custom made by the furnace design the advantages of double balanced weave conveyor belt mesh are flat surface easy cleaning loading and carrying heavy materials.

High temperature belt conveyor furnace.

Belt conveyor ovens each belt conveyor oven is designed and manufactured based on the customer s specific heat process.

Harper s mesh belt conveyor furnaces and kilns are designed for the continuous processing of parts as well as advanced materials such as granular powder or particulate aggregates in high purity and specialty atmosphere environments at temperatures up to 2000 c.

Wisconsin oven manufactures a wide variety of belt conveyor ovens including flat belt style chain conveyors chain edge mesh belt serpentine chain on edge slat type and other arrangements as well as multi tier conveyor ovens.

We can also design an oven to accommodate your existing conveyor.

Electronics mesh belt conveyor furnace high yields of uniform quality products.

The continuous sintering furnace features an excess temperature safety system to guard product against temperature conditions along with easy installation and a competitive price point.

Our experienced engineers will work closely with you to develop a belt conveyor oven to meet your particular requirements for part transport and heating.

These highly efficient and economical furnaces are designed for atmosphere and nonatmosphere applications at temperatures up to 2100 f 1150 c.

Our experience with a variety of belt materials including mesh strip and chain allows us to specify the exact design for your needs for an ideal thermal process solution including gas electric and microwave heated systems.